Since ancient times, man has been looking for ways to effectively fasten different elements together. Today, there are many options for anchoring heavy objects in solid or hollow materials. One of these options is chemical sealing. What do you need to know about this type of fastening? What are its uses? What are its advantages? How to use it effectively? And how to avoid unpleasant surprises? Find out all the answers in this article.

Table of contents

Definition: chemical sealants

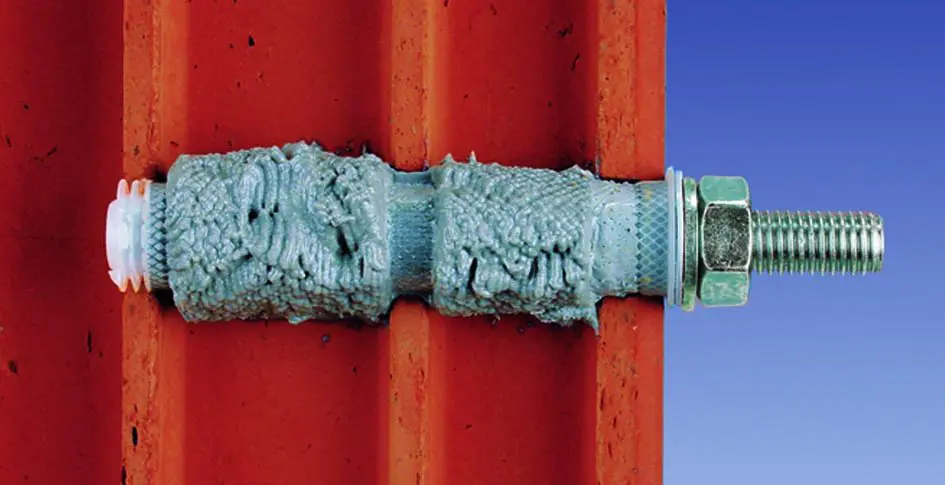

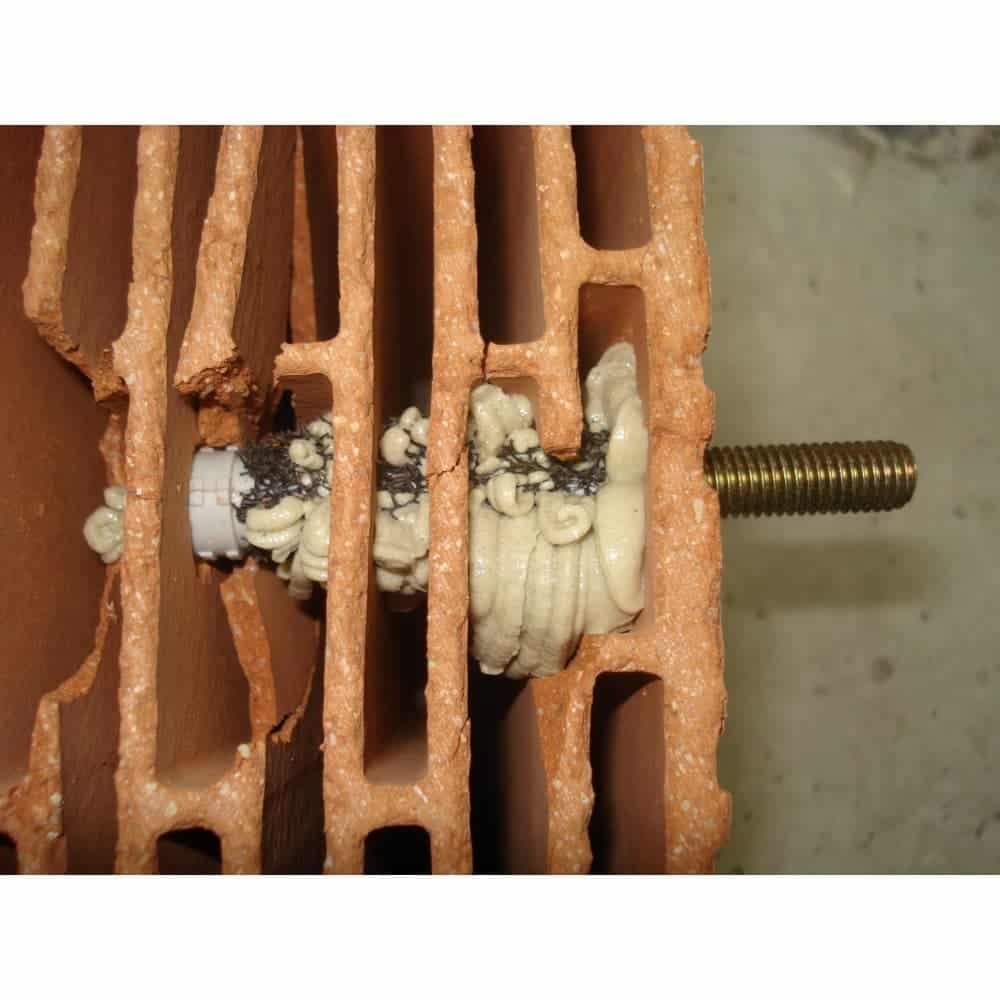

Illustration of how the chemical seal works on an empty substrate

It is used, for example, to fix gates, railings, fences, cumulus heaters, radiators, etc., and replaces the conventional dowel. There are various types of chemical sealant on the market, such as polyester, vinylester, hybrid and epoxy, each with its own advantages and disadvantages.

Tutorial: How to make a chemical seal

Step 1: Choosing the right mortar

It's important to choose the right type of chemical sealant depending on the application and the material on which it will be used. Here's a quick guide to selecting the right product for your needs:

Guide to choosing your chemical sealant :

- Determine the type of material to be fastened : It's important to know whether you're fixing solid or hollow materials, as this will determine which grade of resin to choose.

- Learn about the different types of resins There are several types of resin, each with its own characteristics and uses.

– Vinyl ester resins are ideal for solid or hollow materials and high-risk fixtures such as railings.

– Polyester resins are rather reserved for fixing in hollow materials.

– Epoxy resins offer unrivalled adhesion and are suitable for both cracked and non-cracked concrete. - Choose the container : Chemical sealant can be purchased in a variety of containers, including rigid cartridges, flexible pouches, complete kits with threaded rods and sieves, and single-dose capsules. The choice will depend on your preferences and the quantities required.

- Taking risks into account It's important to be aware of the risks involved in using this product, to read the safety instructions carefully and to observe the precautions for use.

By following these steps, you'll be able to choose the chemical sealant best suited to your fastening needs. Don't forget to refer to the product instructions for optimum use.

Step 2: Drill the wall, taking into account the specific characteristics of the material (hollow or solid).

- For hollow materialMount a drill bit of the correct diameter on the drill, drill the material to the size of the dowel and add 1 cm, clean thoroughly with a swab or cleaning pump to remove dust.

- For solid materialMount a drill bit of the diameter indicated on the threaded rod packaging on the drill, start drilling at slow speed and then speed up, clean the fixing hole thoroughly with a blowgun.

Step 3: Apply the chemical seal, depending on the material.

- For hollow materialInsert the strainer up to the flange, inject the resin from the bottom of the hole and back towards you, position the threaded rod in the strainer, turning it slightly to the right.

- For solid materialInject resin into the hole 2 mm larger than the diameter of the threaded rod, fill the hole with resin, position the threaded rod in the hole.

Allow the resin to harden according to product instructions.

Here's a video explanation:

What materials can be fixed with chemical sealants?

Chemical sealants can be used to fix materials such as metal, ceramics, glass and certain plastics.

It is generally used for industrial or construction applications, such as fastening pipes, electrical conduits, steel beams, floor plates, etc.

It's important to note that the choice of material to be fixed will depend on the properties of the chemical sealant used, as well as on the conditions of use and stress resistance requirements.

What is the drying time for this fastening system?

When using chemical sealants, it's important to respect the drying time, also known as the curing time.

This time varies according to factors such as humidity, room temperature, and the type of resin and hardener used. The manufacturer's instructions can provide information on the drying time required.

It should be noted that low temperatures can slow down the chemical reaction, and that the strength of this mixture continues to increase up to 5 days after application (in the case of epoxy resin). It is therefore important to follow the drying instructions to ensure the quality and durability of the repair.

For Fisher FIS HT resin, for example, handling time is around 5 minutes, and drying time is 60 minutes if room temperature is between 15 and 25°C.

Frequently asked questions about chemical sealants

What is a chemical seal?

Chemical sealing is a fastening process that involves filling a hole in a support material with a resin, which then hardens to ensure a secure hold.

How do I proceed with a chemical seal?

Drill a hole slightly larger in diameter than the threaded rod or rebar to be used, then inject the resin into the hole. In hollow materials, it is advisable to place a sieve in the hole before injection to form a plug that will retain the resin and the fastener.

What drilling diameter for chemical sealants?

We recommend drilling a hole 2 to 6 mm larger in diameter than the threaded rod or rebar to be used.

How much weight can a chemical sealant bear?

The load-bearing capacity of a chemical sealant will depend on many factors, including the composition of the sealant, the surface area of the fastening zone, the size of the fastening zone, temperature and environment, as well as the shape and dimensions of the fastened object.

It is important to note that the maximum load capacity may vary depending on whether the load is applied in tension or compression.

Chemical sealants can withstand heavy loads of up to 1 tonne in concrete, depending on the product used.

How deep should a chemical seal be?

The drilling depth should be at least 8 to 12 times the diameter of the threaded rod or rebar used.

When to use chemical sealants

Chemical sealant is the ideal solution for fixing large, heavy objects such as gates, railings, barriers and cumulus heaters. It is used where high tensile strength and durability are required.

What drilling diameter for chemical sealants?

We recommend drilling a hole of the appropriate diameter: in the case of a chemical seal, it's best to use a hole with a diameter 2 to 6 mm greater than the diameter of the rod or element to be sealed. This will ensure optimum adhesion of the resin to the support material and greater strength of the fastener. It is also important to respect the recommended drilling depth to ensure optimum hold of the fastener.

Now that you know all about chemical sealants, don't hesitate to take advantage of this solution to securely fix all your objects!