| Features | Value |

|---|---|

| Capacity | 2 to 12 bikes |

| Type | Stabilized wheel grip |

| Mounting | Concrete base plate or chemical anchor for paving |

| Material | Galvanized steel (tube 19×1.5 mm, frame L 35×35×3 mm) |

| Finish | Galvanized (RAL powder coating available) |

| Spacing | 400 mm between axes |

| Max. tires | Up to 56 mm wide |

| Warranty | 5 years (if installed on concrete slab or blocks) |

To install a galvanized steel bicycle rack safe and stable, it's crucial to choose the right floor. Here are the different types of flooring available, along with recommended installation methods for each configuration:

Benefits Concrete is the ideal surface on which to install a bike rack. It's solid, durable and holds up well over time.

Installation The rack can be attached directly using bolt-on plates in concrete, or permanently anchored with a sealing in concrete blocks.

Disadvantages : The cost of a slab or concrete blocks can be considerable, depending on the surface to be landscaped.

Benefits Asphalt is widely used, especially for parking lots and access roads.

Installation : It is not advisable to fix a rack directly into the asphalt alone. A concrete slab or localized concrete studs are strongly recommended to guarantee stability and prevent any tearing off.

Disadvantage Preliminary floor preparation (concrete slab or blocks) increases costs.

Benefits Aesthetically pleasing and frequently used in pedestrian zones and town centers.

Installation It is advisable to remove some cobblestonesto cast a concrete stud under the surface, then secure the rack to this stud before lay the cobblestones around the base.

Installation : As these surfaces are soft, a concrete base is essential for securing the rack. The rack is dug out, a concrete base is poured and then fixed in place. Gravel or sand can then be placed around it.

Note Without a solid base, the rack could tip over or sink into the ground.

Installation : As with furniture surfaces, it is essential to install a concrete footing to guarantee rack stability. Allow for sufficient depth to prevent movement due to humidity or soil compaction.

we're looking for the document in the archives...

Discover also our complete range of'bicycle shelters to meet all your parking needs.

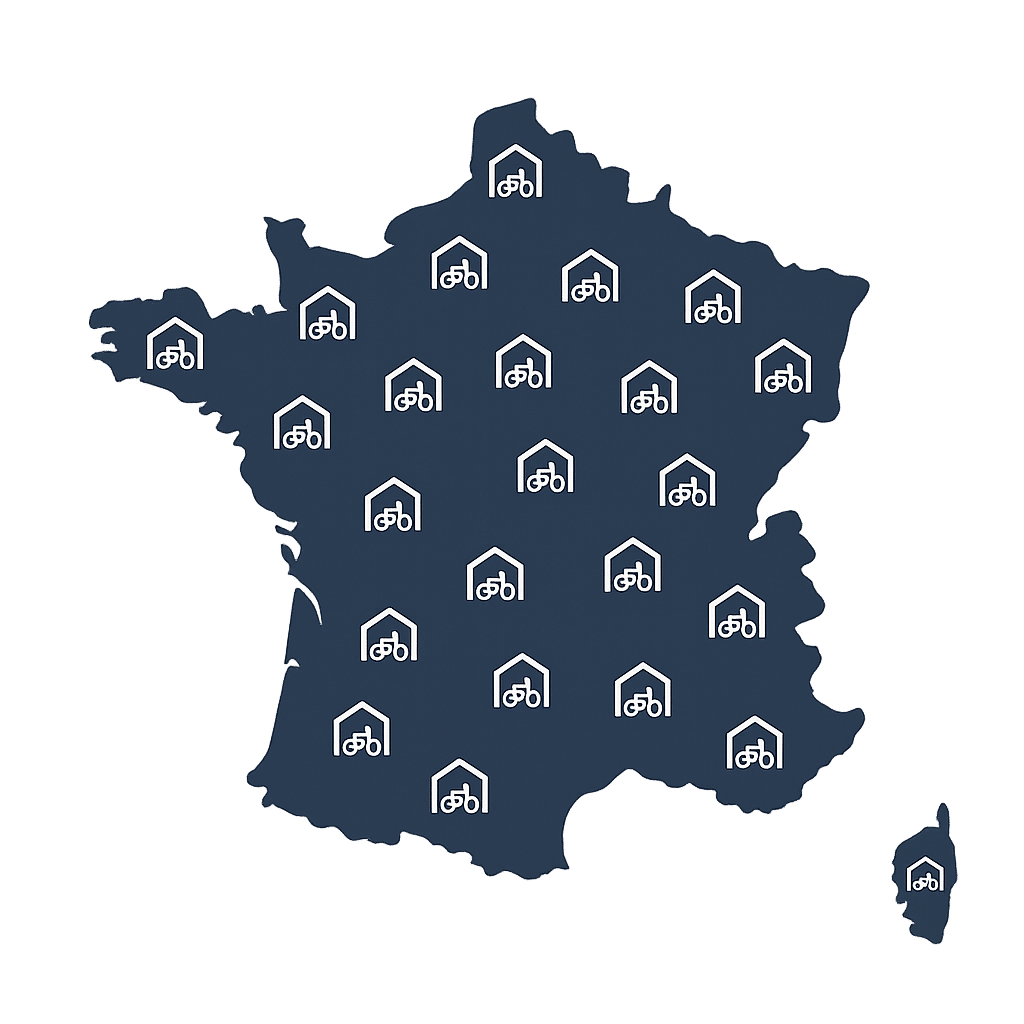

With a team available as close to you as possible.

ByCommute can also take care of civil engineering (concrete studs and concrete slabs).

Yes, the Taillefer hoop accepts city bikes, mountain bikes and electric bikes.

With 400 mm spacing between supports and a tire width of up to 56 mm, it's even suitable for wide models or those with a front basket.

At ByCommute, your opinion counts. That's why we offer several customization options for our bike hoops to meet the specific needs of each customer. Here are just some of the options available:

We understand that price is an important factor in our customers' decisions. That's why it's possible to benefit from financial aid for the purchase of bicycle racks, particularly for companies and public bodies wishing to promote soft mobility. Here's some detailed information on these grants:

We are a supplier of Alvéole program : This program, supported by the French government, offers grants to finance the installation of secure bicycle parking facilities, including bicycle racks. Subsidies can cover up to 60% of the total cost of the installation. Find out more!

We are also OEPV supplier: Companies are included in this program and can also help you cover up to 60% of the total cost of the installation. Find out more!

Please note: these programs also subsidize bike storage, racking, installation and transport.

Many local authorities have funds available to support soft mobility initiatives, including the installation of bicycle racks.

To install a galvanized steel bicycle rack safe and stable, it's crucial to choose the right floor. Here are the different types of flooring available, along with recommended installation methods for each configuration:

Benefits Concrete is the ideal surface on which to install a bike rack. It's solid, durable and holds up well over time.

Installation The rack can be attached directly using bolt-on plates in concrete, or permanently anchored with a sealing in concrete blocks.

Disadvantages : The cost of a slab or concrete blocks can be considerable, depending on the surface to be landscaped.

Benefits Asphalt is widely used, especially for parking lots and access roads.

Installation : It is not advisable to fix a rack directly into the asphalt alone. A concrete slab or localized concrete studs are strongly recommended to guarantee stability and prevent any tearing off.

Disadvantage Preliminary floor preparation (concrete slab or blocks) increases costs.

Benefits Aesthetically pleasing and frequently used in pedestrian zones and town centers.

Installation It is advisable to remove some cobblestonesto cast a concrete stud under the surface, then secure the rack to this stud before lay the cobblestones around the base.

Installation : As these surfaces are soft, a concrete base is essential for securing the rack. The rack is dug out, a concrete base is poured and then fixed in place. Gravel or sand can then be placed around it.

Note Without a solid base, the rack could tip over or sink into the ground.

Installation : As with furniture surfaces, it is essential to install a concrete footing to guarantee rack stability. Allow for sufficient depth to prevent movement due to humidity or soil compaction.

Le rack Taillefer permet une sécurisation en 2 points : roue avant et cadre. Il est compatible avec tous les antivols de type U ou chaînes longues. La structure en acier galvanisé résiste aux tentatives d’arrachement, garantissant une protection optimale contre le vol.

Choisir le rack Taillefer unilatéral, c’est opter pour la solution Taillefer la plus économique :

💡 Nos recommandations selon votre projet :

Your details will only be used to send you the data sheet.

How to install bike racks